(This article is reproduced from Chongchuan Online)

"On the circuit of chip sealing loading plate, FC-BGA sealing loading plate, which is independently developed by us and owns our own intellectual property rights, will be mass-produced next month, representing the world's advanced technology."

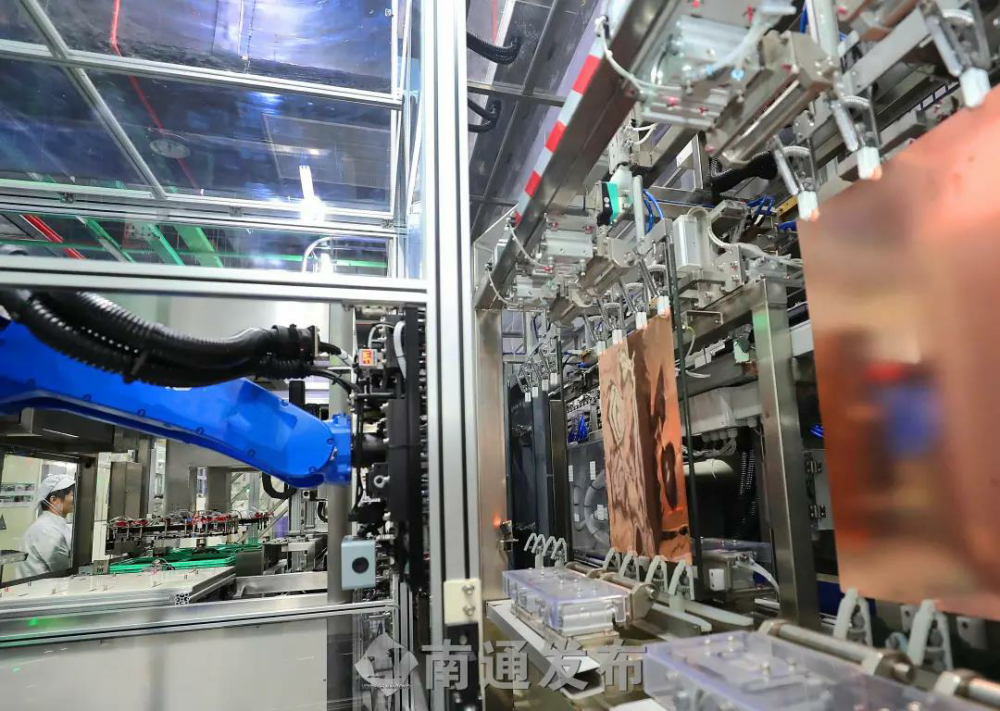

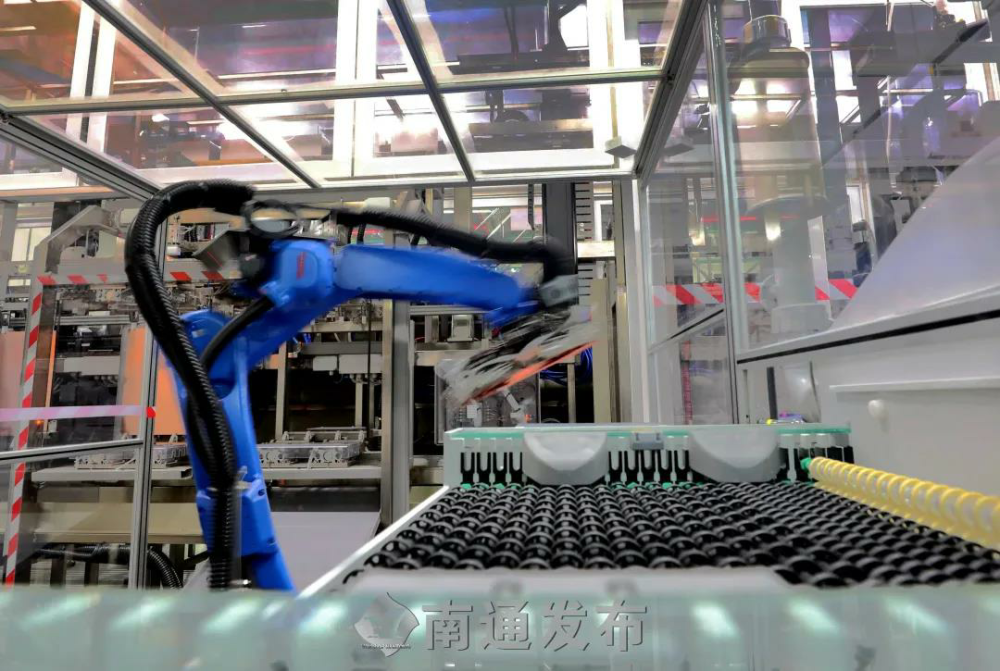

In the face of Western barriers, domestic chips are accelerating their efforts to break through. On the 7th, the reporter interviewed in Nantong Yueya Semiconductor Co., LTD., and heard the latest news released by the relevant person in charge of the company. All the people present were excited for it.

Nantong VietAsia was established on May 31, 2018, located in Nantong Science and Industry Park, a key integrated circuit industry cluster in Chongchuan District. Its parent company, Zhuhai Yueya Semiconductor, is a leading enterprise in the domestic industry, focusing on the research and development and manufacturing of high-end organic coreless sealing loading plate. It is the first enterprise in the world to realize the mass production of coreless sealing loading plate by using the "copper column layer adding method".

"To use an imperfect metaphor, the plate is to a chip what water is to a cup."

Specifically, a complete chip is composed of a bare chip (wafer) and an packaging body (sealing plate and sealing materials, leads, etc.). Sealing and loading plate is the core material of chip packaging. Its role is reflected in two aspects: on the one hand, it can protect, fix and support the chip, enhance the heat conduction and heat dissipation performance of the chip, and ensure that the chip is not physically damaged; On the other hand, the upper layer of the loading board is connected to the chip, and the lower layer is connected to the printed circuit board to achieve electrical and physical connection, power distribution, signal distribution, and communication between the internal and external circuits of the chip.

The chip is integrated with high precision and high density. As the carrier board to carry the chip, the technical process of the product is very high. For a long time, the technology, process, materials and equipment of high-end loading plate are almost monopolized by foreign enterprises. Domestic enterprises have weak technical force, lack of customer resources, and less investment in R&D of high-end sealing and loading plate.

"At present, the scale of the domestic carrier market only accounts for about 10% of the global market, and the products are mainly used in the middle and low end of lead bonding package." Relevant person in charge of the company introduced that the world's main manufacturers of sealing plate are concentrated in Taiwan, South Korea and Japan.

In such a highly monopolistic and competitive market, Nantong Yue Ya rely on what a "Yue" and rise?

A company official said that the key to VietAsia Semiconductor's high quality development is innovation and continuous innovation.

Zhuhai Yueya, the parent company of Nantong Yueya, is jointly invested by Founder Group and Israel AMITEC. Since its establishment in 2006, it has continuously carried out technological iterations on the track of sealing and loading plates. The company's products have evolved from a single RF front-end IC carrier board to a number of product lines such as processor IC carrier board, power management module and flip chip module. Today, our products are widely used in RF modules for analog chip packaging, baseband, application processors, embedded chips and glass carrier plate solutions for digital chips.

Hundreds of patent certificates issued by the United States, Japan, South Korea and other countries are hung on three circular display walls in the exhibition hall of Nantong Yueya.

Related person in charge of Nantong Yuya said, "This is only a small part of the company's invention patent." Leading technology, win the market opportunity. At present, VietASIA Semiconductor has become China's largest shipments of IC packaging plate, semiconductor devices, semiconductor module research and development manufacturing enterprises. Rf module board accounts for 35% of global shipments, power management module technology is the world's leading, the main customers are the world's leading semiconductor enterprises.

"From the global market, the design and manufacture of electronic information products mainly towards high frequency, high speed, light, small, thin, portable development and multifunctional system integration direction, based on the sealing board of high-end integrated circuits, which has become the mainstream of the market."

According to the relevant person in charge of Nantong Yuya, the FC-BGA developed and produced by Nantong Yuya has an airborne board, which has higher integration, better heat dissipation and more stable signal conductivity, and can better meet the development needs of thin and miniaturization of the whole industry. "This technology fills the gap of domestic high-end sealing and loading plate, and breaks the monopoly of foreign high-end sealing and loading plate manufacturers." As a result, Nantong VietAsia has become the first enterprise in China to realize independent research and development of FC-BGA carrier board and realize mass production.

"Thanks to Nantong's favorable business development environment, unique location and industrial cluster advantages, Nantong VietAsia's development has exceeded expectations!" Relevant person in charge of the company said that the layout of Nantong is a strategic decision for the development of VietAsia semiconductor. "In the Yangtze River Delta region, Tongfu micro power, Changdian technology, Huatian Technology and other three domestic sealing and testing factories, are Nantong Yue Asia Semiconductor long-term partners."

It took less than 2 years from the project signing and landing to the final production of Nantong Yueya, while the real construction period was less than 13 months. The achievement of each milestone node is sufficient to prove the efficient government environment of Nantong.

There is no limit to innovation and development is on the way. With innovation as the "basis", to promote the realization of leapfrog development, Nantong Yueya "ran" out of the acceleration.

The development of integrated circuit industry has become a key national strategy. It has become the consensus of the industry to build an autonomous, controllable and open chip industry. "In this context, Nantong Yueya research and development production of high-end sealing plate, become more and more enterprises import substitution, product demand." For the development prospect, Nantong Yue Asian people full of confidence. An official of the company said, "The company strives to become the world's leading packaging plate, semiconductor module and semiconductor device solution provider in 2025, ranking the fifth in the world and the first in China."

Source URL:https://new.qq.com/omn/20210611/20210611A063X300.html